Offsite Construction

Is the term used to describe the range of offsite manufacturing techniques used to build high quality homes faster, with less waste, under closely controlled conditions using a variety of methods which are explained below.

Volumetric Modular

Three dimensional structural units which are manufactured in controlled factory conditions from a combination of steel and timber before delivery to site for erection by crane onto prepared foundations. The level of fitting out can vary from the basic weathertight module complete only with windows and doors, to a fully fitted module complete with external finishes, internal mechanical and electrical services and internal finishes including staircases, kitchens and bathrooms.

Timber Frame

The overall timber frame wall system incorporates a number of different elements from outside to in, these include:

- External cladding and cavity (brick, render, composite or timber boarding) to provide weather resistance.

- Breather membrane to provide weather protection during the build and ensure the frame breathes and resists moisture penetration during its life.

- OSB (oriented strand board) or Plywood lining fitted to the frame to provide strength and rigidity.

- Wall insulation fitted between the structural studs to enhance thermal performance and lower energy bills. In the case of ‘open’ panels this is done on site but with ‘closed’ panels it is fitted in the factory.

- Vapour control layer (VCL) to prevent interstitial condensation and limit air leakage.

- Service zone to distribute electrical and mechanical systems.

- Plasterboard for fire resistance and internal finishes.

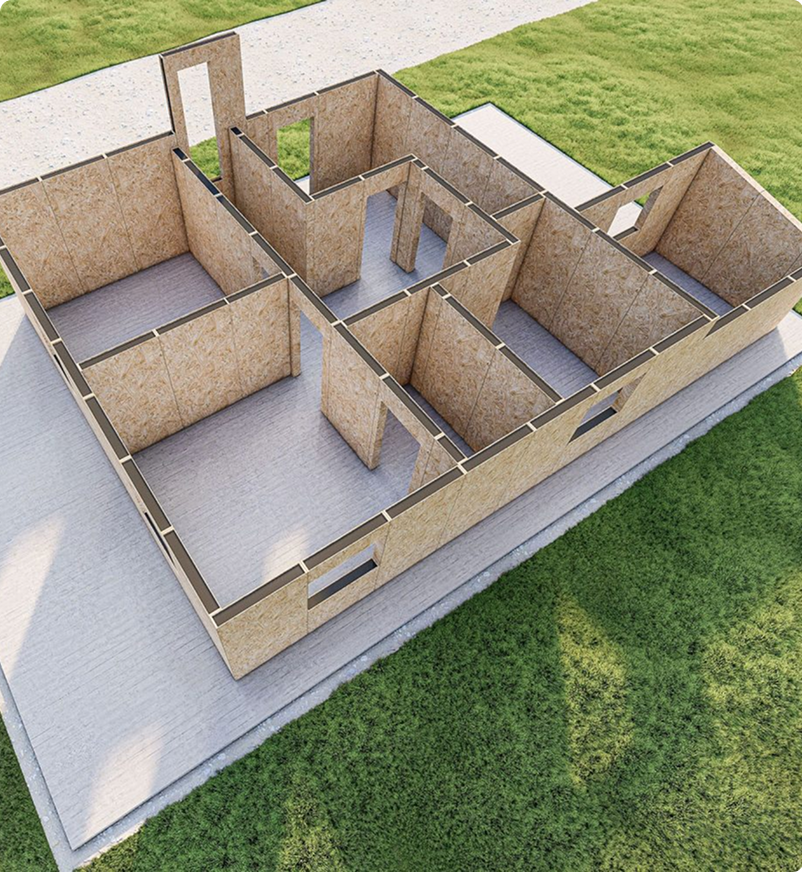

Structural Insulated Panels (SIPs)

The overall SIP wall system incorporates a number of different elements from outside to in, these include:

- External cladding and cavity (brick, render, composite or timber boarding) to provide weather resistance.

- Breather membrane to provide weather protection during the build and ensure the frame breathes and resists moisture penetration during its life.

- SIP incorporating wall insulation fitted between the structural panels to enhance thermal performance and lower energy bills.

- Vapour control layer (VCL) to prevent interstitial condensation and limit air leakage.

- Service zone to distribute electrical and mechanical systems.

- Plasterboard for fire resistance and internal finishes.

Fusion Log

The Fusion log is manufactured from six sections of Finnish pine that are laminated crosswise. Pioneering Fusion™ technology uses vertical, non-settling, cross-laminated solid wood beams to create a state-of-the-art superstructure which gives all the benefits of a timber-frame together with the solidity of traditional block work with far less environmental impact.

In the UK to comply with Building Regulations the construction is made up as follows from outside to in.

- Honka laminated timber panel exterior which provides water proofing and fire resistance.

- Insulation and service zone

- Plasterboard for interior finishes

Light Gauge Steel

The building structure is formed from panels made up from individual c sections of light gauge steel. These panels are then clad externally to create a weatherproof envelope. Insulation is fitted within the panels.

The overall light gauge steel wall system incorporates a number of different elements from outside to in, these include:

- External cladding and cavity (brick, render, composite or timber boarding) to provide weather resistance.

- Boardex cladding to provide fire and moisture resistance

- Light gauge steel frame with insulation and service zone to distribute electrical and mechanical systems.

- Plasterboard for fire resistance and internal finishes.

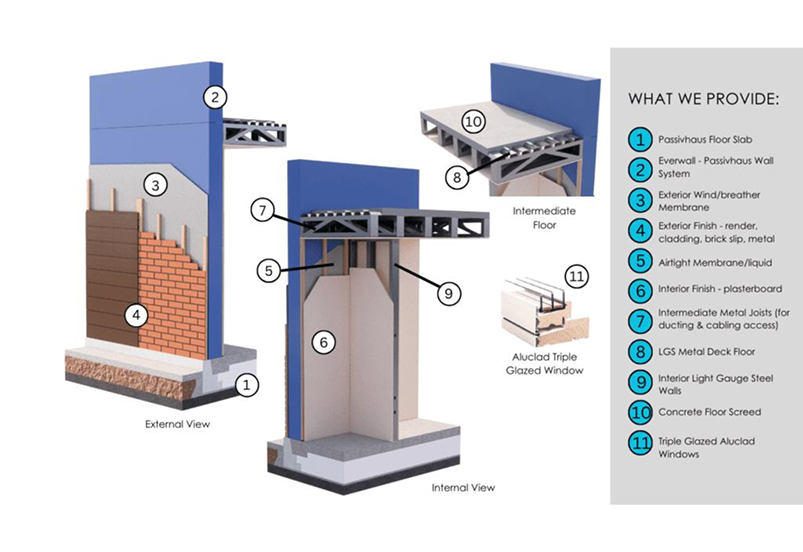

Specialist Products from our Partners

The Structurally Insulated Steel panel system can be used on any house build project irrespective of individual design requirements. It is created using thermally strengthened light gauge steel, insulated and clad on both sides with a A1 fire board.

The system is designed to work with a well constructed passive floor slab as well as triple glazed Aluclad windows all within a passive house framework.

PHPS is panelised off-site and assembled on site, which decreases overall project build times. Each house is individually designed and the walls, floors and roof panels are precisely made in the factory in line with the architect’s requirements.

The PHPS is designed to stringent Passivhaus standards. The standard wall section and roof section thickness provides a U value of 0.13W/(m2k) each. The building envelope is constructed using the PHPS system, giving a continuous insulation layer around the house. The internal walls are made in light gauge steel.

Passive House systems are normally associated with very high costs – Everhaus PHPS makes passive house affordable to all.

- The panels are insulated in the factory with EPS/XPS (other materials are also available)

- The outer face of the panels has a wind/breather membrane.

- External cladding can be brick, brick slips, render, composite or timber boarding to provide weather resistance and meet planning requirements.

- The internal face of the panels is provided with an airtight membrane.

- The inner face of the panels has a service zone to distribute electrical and mechanical systems and plasterboard for fire resistance and internal finishes.

- The internal walls are light gauge steel studwork with plasterboard.

- Upper floors are light gauge steel floor deck with concrete floor screed creating a thermal mass as well as a strong upper floor area which is sound proof and has the option of under floor heating within the slab.